DMA Engineers’ mechanical, electrical and hydraulic design teams were engaged to assist with design and construction of the refurbishment including:

- new air conditioning systems

- steam plan upgrade

- water quality upgrades

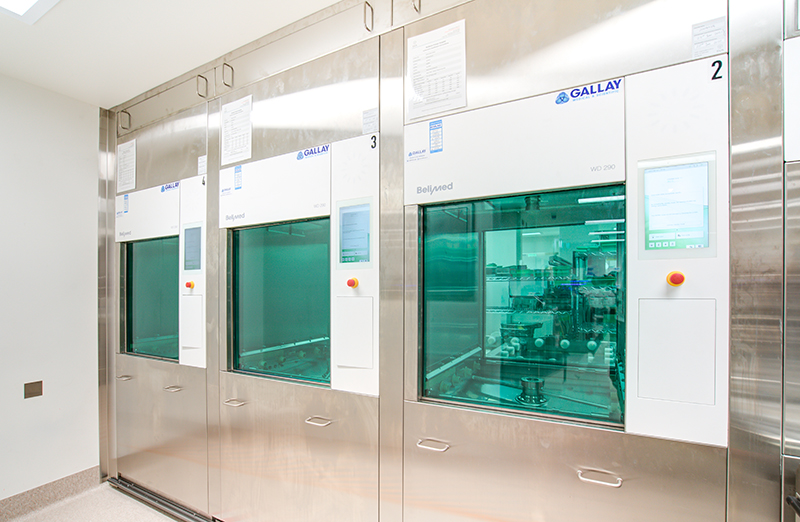

- new sterilisation equipment design

- layout changes to improve functionality

The upgrade project was completed in nine stages to ensure the existing CSSD remained operational at all times. Given continued use and extensive existing site constraints, design and installation methodologies had to be carefully considered and coordinated with all stakeholders. Some of the features of our design included:

- Our hydraulic team designed flow and return hot and RO water systems that could be installed in each stage and then extended into the next. One of the challenges of this approach was ensuring contractors could connect to the services installed in the previous stage without the need to shut down the previous stage of works. We were able to do this by installing 3-way stainless steel isolation valves.

- With limited as-built information for the site and the discovery of non-compliant existing services, our hydraulic team organised for non-invasive testing of the existing cold and soft hot water systems, with no shutdowns required. The testing results gave us the current flows, pressures, velocities and temperatures of the water. We conducted this test for a whole week so we were able to achieve accurate results and ensure that the existing system had the capacity for the new installation.

- The key challenge our mechanical team had to overcome was maintaining operation throughout construction whilst significantly altering the department layout, zoning and sterilisation plant served. In order to overcome these constraints staging and cutovers had to be carefully designed and coordinated. Ultimately the following new mechanical elements were successfully implemented:

- New low-pressure and high-pressure steam manifolds.

- New steam condensate recovery system (resulting in significant gas boiler savings).

- New supplementary air handling units and conversion of existing with the addition of active humidity control.

- Conversion of sterilisers from portable water cooling to chilled water (resulting in significant water savings).

- New chiller to accommodate additional cooling demand.

- Our electrical team had the challenge of utilising existing equipment and tailoring a design to minimise the amount of rework and redundant installation through a complicated staging process. We used conduits to bypass completed stages and nullified the need to access already completed stages thus keeping the space continually operational.

The project was completed in early 2021 whilst maintaining operation throughout the construction program. The upgraded CSSD has successfully achieved compliance, and improved quality and functionality for staff,